Texlon Plastics Corporation Specializes in Injection Molding Services and Precision Mold Making & Mold Repair

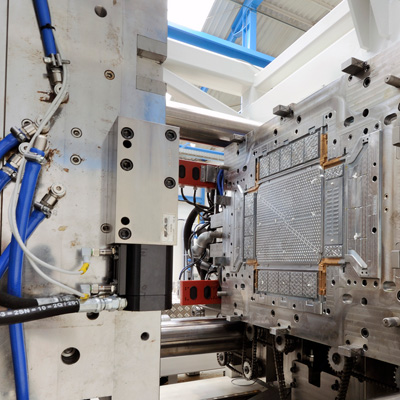

Injection Molding Services

Full Service Custom Injection Molding Since 1976

- High Quality Injection Molded Parts Custom Made in the USA

- Experts in a Wide Variety of Industries, Materials, Sizes, and Applications

- Large Array of Injection Molding Presses for Most Part Sizes

- 50+ Years Experience in Insert Molding & Overmol...

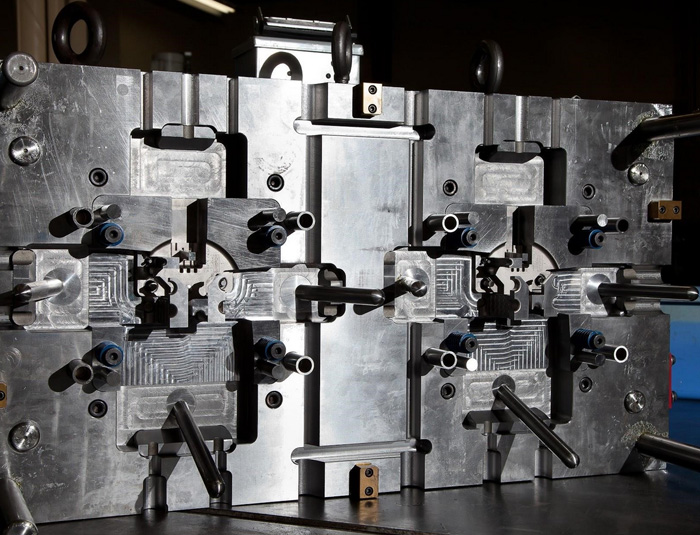

Precision Mold Making & Product Design

- Full Service Tool & Die Department

- High Production Multiple Cavity Injection Molds

- Single Cavity Injection Molds

- Aluminum Prototype Injection Molds

- 3D Printing, Prototyping, and Small Batch Runs

- Product Design and CAD Assistance

Value Added Services / Secondary Operations

- Post-Molding Operations

- Design CAD Assistance

- Insert Molding

- Prototyping

- Complete Tool & Die Department for Rapid Mold Modification and Repair

Service and delivery: Our team will work directly with you in order to provide you with the attention needed to solve your problem or problems. Our sales pe...

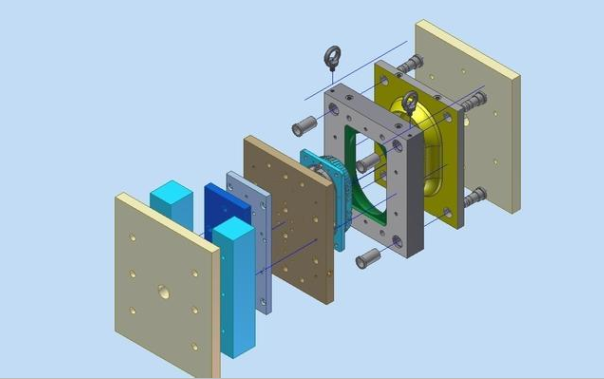

Mold Design & Tooling

Leveraging our internal proficiency guarantees excellence from the very outset. Enhance the quality, dependability, and ease of manufacturing for your components. Expedite your path to market success. We understand that prosperous components originate from impeccably crafted molds. Armed with our in-house mastery in mold design and tooling, extensive familiarity with diverse materials, application insights, and proficient capabilities, we fabricate tailored injection molds and shepherd your products from conception to manufacturing.

Engineered Solutions

For many years, we've been a go-to solution for tailored plastic injection molding and tooling challenges. Recognizing that design plays a pivotal role, influencing 80% of the cost of a molded part, we understand that engineering considerations significantly impact cost-effectiveness and overall performance. Our exclusive and meticulous mold design approach guarantees that the components we deliver are cost-efficient to manufacture while consistently delivering reliable performance in the market.

Choosing the Right Materials for Your Part

Pinpointing the optimal plastic material for your specific application stands as a crucial step in crafting a triumphant end product. Every material boasts distinct traits, properties, and advantages. Through collaborative engagement with you and your custom plastic injection molding venture, we guide you in selecting the most suitable and cost-efficient approach to realizing your objectives while adhering to regulations. Our inventory is expansive, encompassing a spectrum from engineering plastics to commodity plastics.

Advantages of Injection Molding

Texlon Plastics stands out as a premier provider of injection molding services, offering a host of advantages crucial for diverse industries. Specializing in the efficient production of large quantities, Texlon Plastics ensures high-speed manufacturing with a focus on precision and complexity. The company's commitment to consistency and repeatability is evident in the production of intricately shaped components, facilitated by the versatility of materials available in injection molding. Texlon Plastics' services prove cost-effective for large-scale productions, minimizing waste through material recycling. With seamless automation integration, the company enhances production efficiency and maintains a commitment to design flexibility, enabling the creation of innovative and unique products. Texlon Plastics excels in delivering parts with superior surface finishes and fine details, making them a trusted partner for businesses of all sizes and stages—from prototyping to high-volume production—reflecting the scalability and reliability inherent in their injection molding services.

Materials Available

Texlon Plastics, a distinguished provider of injection molding services, offers a diverse range of materials tailored to meet specific client needs. Specializing in the injection molding process, Texlon employs an array of thermoplastics, including Polyethylene, Polypropylene, Polystyrene, Polyvinyl Chloride, and Polycarbonate, among others. Additionally, the company utilizes thermosetting plastics such as Phenolic and elastomers like Silicone and Polyurethane. Texlon Plastics is well-versed in engineering plastics like Nylon, Polyethylene terephthalate, and Acetal, ensuring suitability for varied applications. With a commitment to innovation, the company may also explore biodegradable options such as Polylactic Acid. This comprehensive material selection allows Texlon Plastics to deliver high-quality, precisely molded components, meeting the diverse and stringent requirements of its clientele.

Industries Served

As a leading provider of injection molding services, Texlon Plastics serves an array of industries by delivering high-quality plastic components with precision and efficiency. In the automotive sector, Texlon contributes to the production of interior and exterior components, while in the consumer goods industry, the company manufactures packaging, containers, and toys. The electronics industry benefits from Texlon's expertise in crafting casings and connectors for electronic devices. Additionally, Texlon plays a vital role in the medical field by producing components for medical devices, ensuring precision and cleanliness. The aerospace industry relies on Texlon for lightweight, high-strength components, while the packaging industry benefits from the company's efficiency in producing containers and closures. Texlon Plastics also contributes to the construction sector with parts like pipe fittings, and the company's reach extends to appliances, toys, industrial equipment, sporting goods, and furniture. With a diverse portfolio and a commitment to meeting industry-specific requirements, Texlon Plastics is a trusted partner across various sectors, offering expertise in material selection, mold design, and the cost-effective production of plastic components.

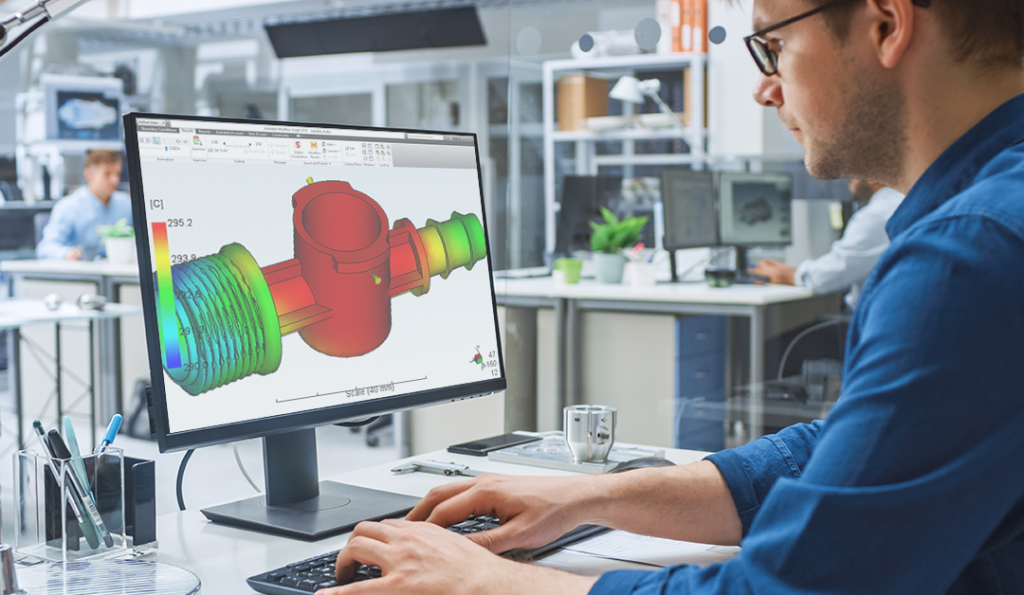

CAD Design

Texlon Plastics leverages cutting-edge Design CAD technology to enhance and streamline the design process across various industries. As a crucial step in our injection molding services, Texlon utilizes CAD software to create detailed 2D and 3D models of plastic components. This advanced technology empowers our engineers and designers to draft, visualize, and analyze designs before the actual manufacturing process begins. With a focus on precision, parametric design, and simulation, Texlon ensures that designs meet the highest standards for functionality and efficiency. The integration of CAM tools further facilitates a seamless transition from design to production, solidifying Texlon Plastics' position as a forward-thinking and efficient partner in the creation of high-quality plastic components for diverse applications.

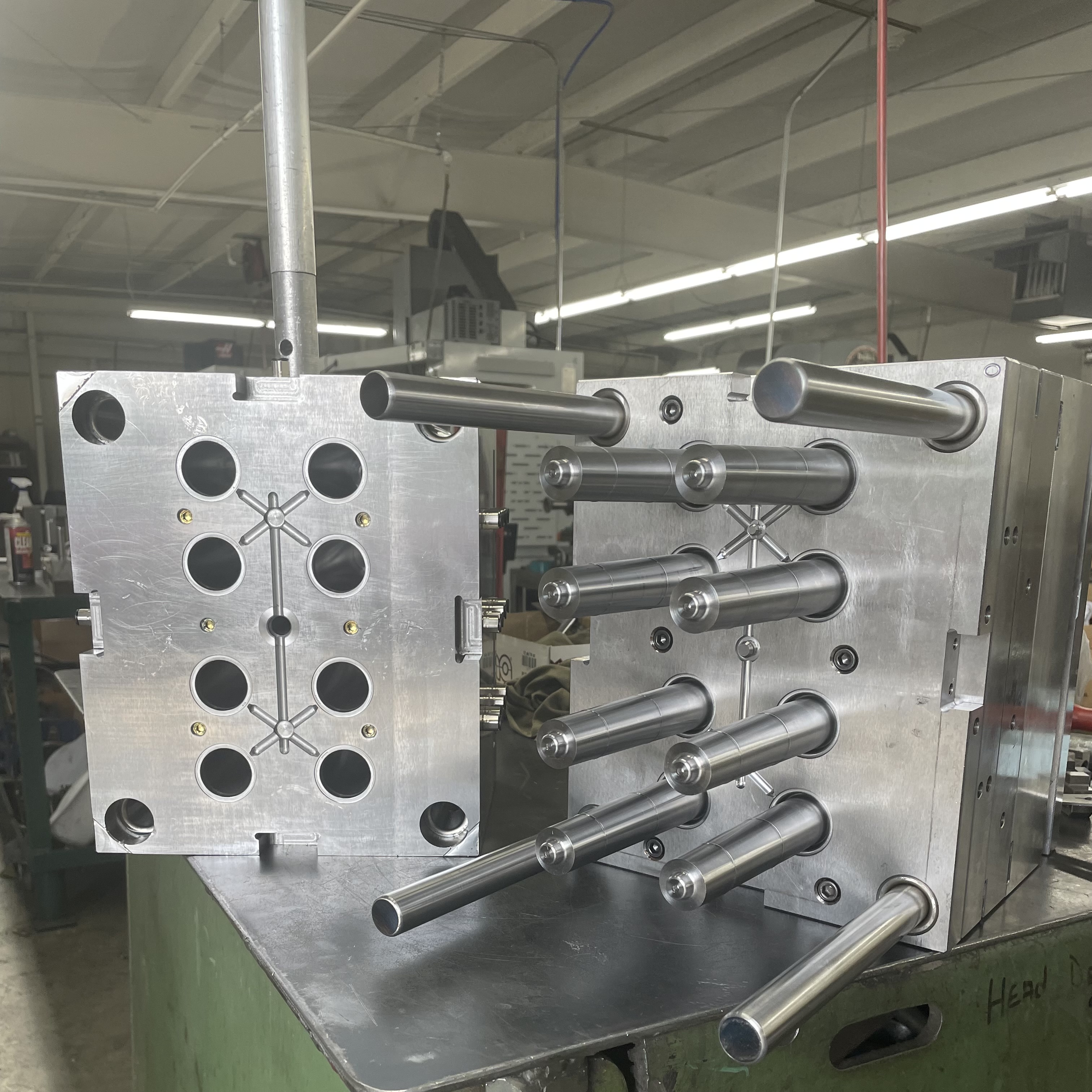

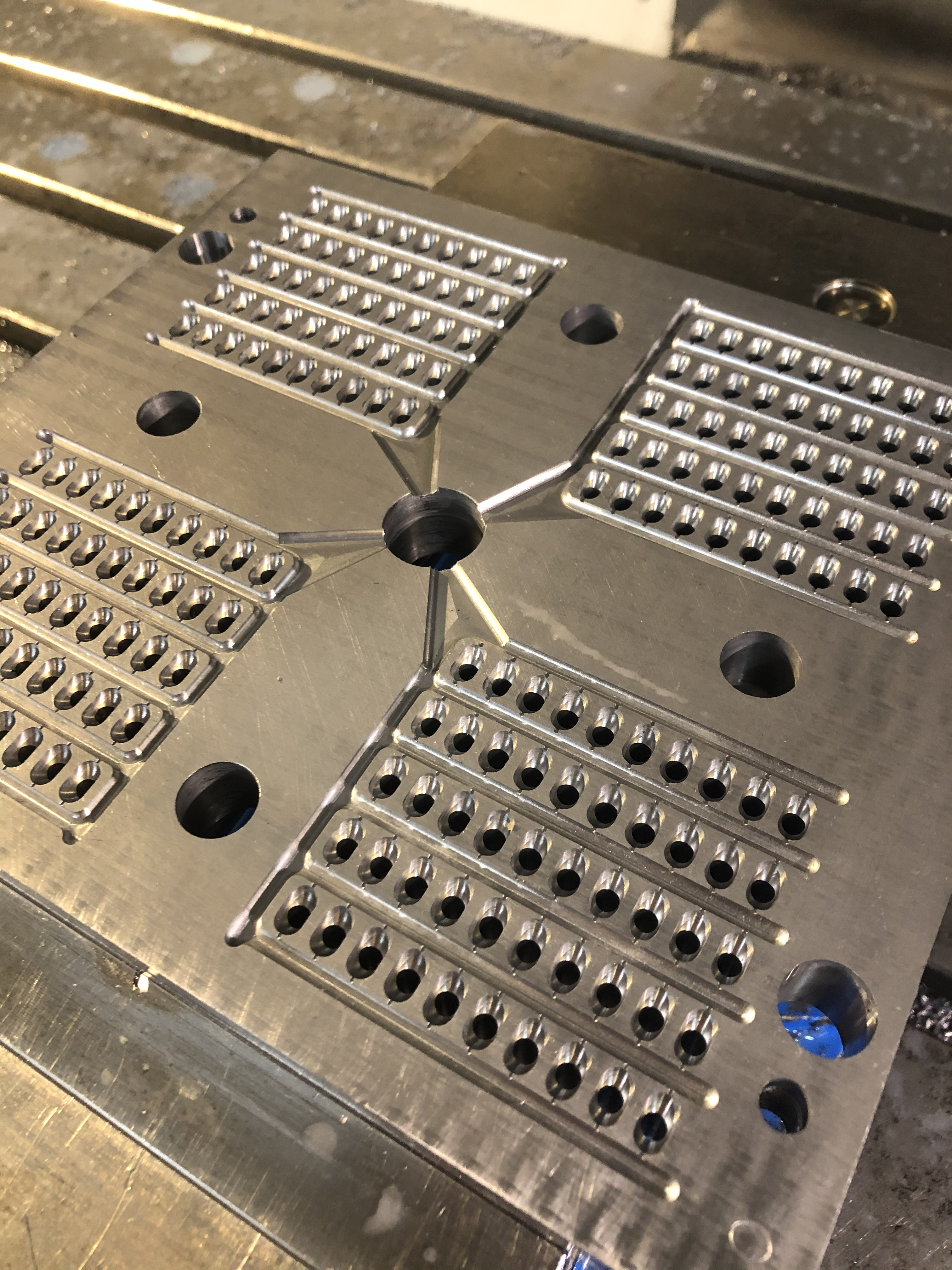

High Production Multiple Cavity Injection Molds

High Production Multiple Cavity Injection Molds are specialized molds used in injection molding for simultaneous production of multiple identical parts in a single cycle. These molds, with more than one cavity, ensure precision and consistency in the molding process, reducing cycle time and overall manufacturing costs. The increased efficiency makes them particularly suitable for high-volume production in industries like automotive, consumer goods, and electronics. Texlon Plastics utilizes these molds as part of their injection molding services, enabling us to meet the demands of clients requiring large quantities of precision-molded plastic components with cost-effective and timely production.

Mold Modification and Repair

A Complete Tool & Die Department for Rapid Mold Modification and Repair is an integral facility within manufacturing or injection molding companies, specializing in the design, fabrication, modification, and repair of molds used in the injection molding process. Equipped with skilled professionals and utilizing advanced technologies like Computer-Aided Design (CAD), the department ensures precision in creating new molds and swiftly modifies existing ones in response to design changes or production issues. Rapid mold modification and repair capabilities contribute to minimizing downtime, enhancing overall production efficiency, and maintaining high standards of product quality. This comprehensive in-house capability allows companies, such as Texlon Plastics, to have control over the entire mold lifecycle, facilitating adaptability to changing production needs and ensuring the seamless operation of their injection molding services.