Value Added Services / Secondary Operations

- Post-Molding Operations

- Design CAD Assistance

- Insert Molding

- Prototyping

- Complete Tool & Die Department for Rapid Mold Modification and Repair

Service and delivery: Our team will work directly with you in order to provide you with the attention needed to solve your problem or problems. Our sales personnel will be glad to supply your company with quotes as well as information on any matter relating to scheduling and delivery. Samples are available upon request and all information will remain confidential.

We strive to give our customers a quality product and we feel that this should begin with the building of the molds, through setup and production of the part.

-

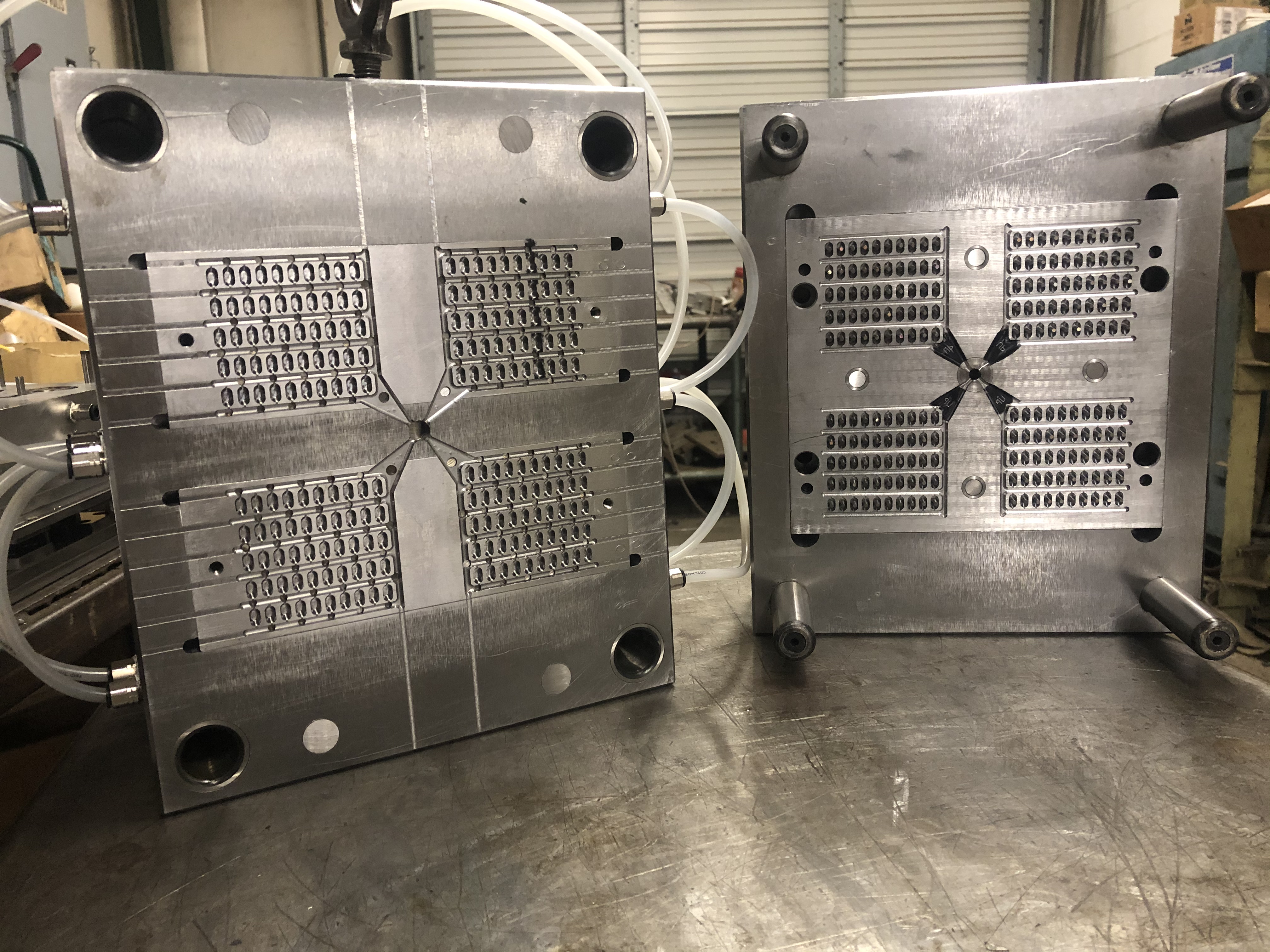

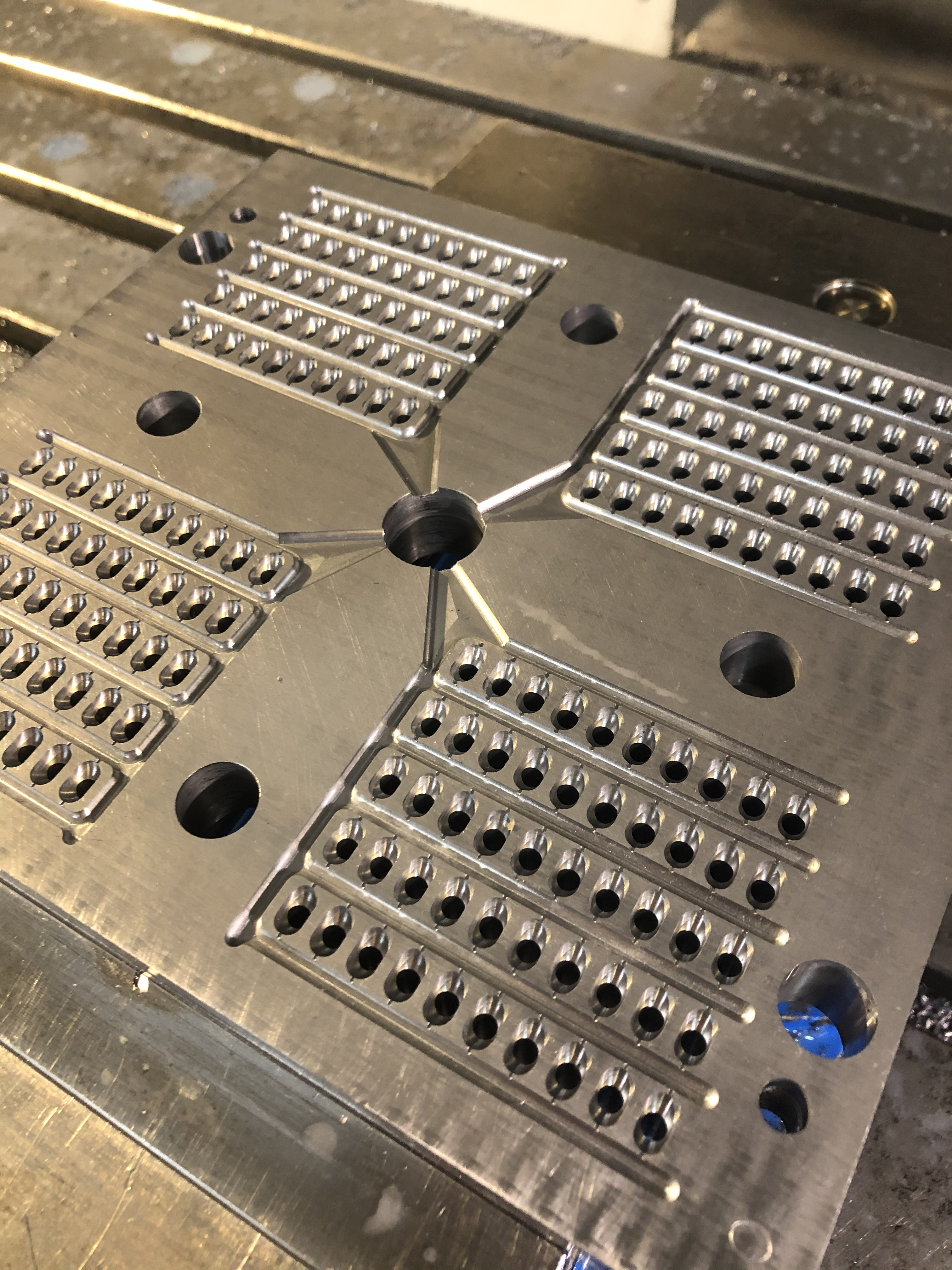

200 Cavity Injection Mold for Face Mask Adjusting from Design to Manufacturing

200 Cavity Mold for facemask adjustment part from design to manufacturing in 7 days. After a 2nd identical mold was engineered, over 55 million pieces were produced over a 7 week period during supply chain shortages and the pandemic. Custom made in North Carolina, USA...

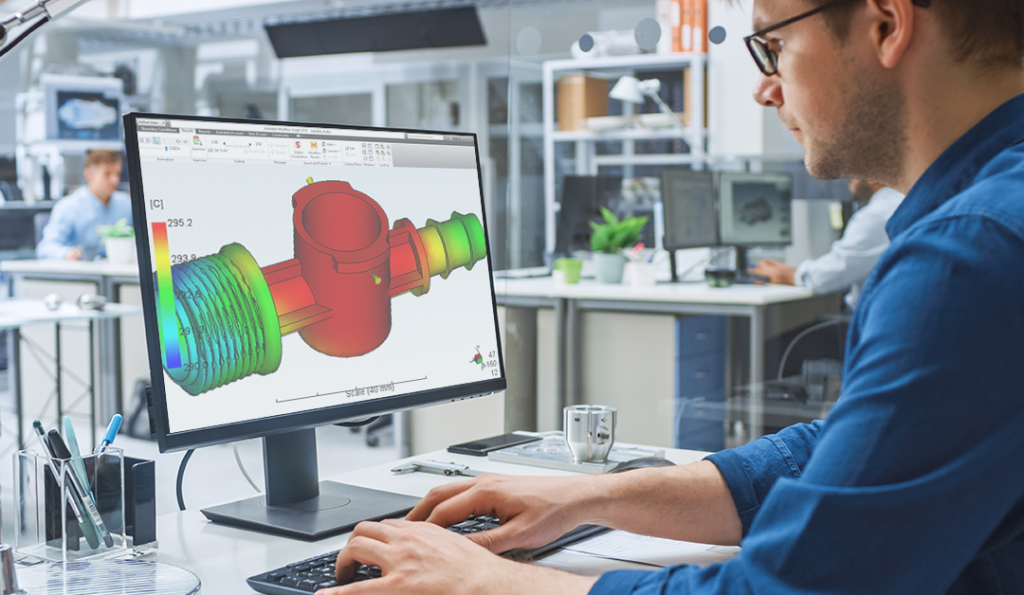

CAD Design

Texlon Plastics leverages cutting-edge Design CAD technology to enhance and streamline the design process across various industries. As a crucial step in our injection molding services, Texlon utilizes CAD software to create detailed 2D and 3D models of plastic components. This advanced technology empowers our engineers and designers to draft, visualize, and analyze designs before the actual manufacturing process begins. With a focus on precision, parametric design, and simulation, Texlon ensures that designs meet the highest standards for functionality and efficiency. The integration of CAM tools further facilitates a seamless transition from design to production, solidifying Texlon Plastics' position as a forward-thinking and efficient partner in the creation of high-quality plastic components for diverse applications.

High Production Multiple Cavity Injection Molds

High Production Multiple Cavity Injection Molds are specialized molds used in injection molding for simultaneous production of multiple identical parts in a single cycle. These molds, with more than one cavity, ensure precision and consistency in the molding process, reducing cycle time and overall manufacturing costs. The increased efficiency makes them particularly suitable for high-volume production in industries like automotive, consumer goods, and electronics. Texlon Plastics utilizes these molds as part of their injection molding services, enabling us to meet the demands of clients requiring large quantities of precision-molded plastic components with cost-effective and timely production.

Mold Modification and Repair

A Complete Tool & Die Department for Rapid Mold Modification and Repair is an integral facility within manufacturing or injection molding companies, specializing in the design, fabrication, modification, and repair of molds used in the injection molding process. Equipped with skilled professionals and utilizing advanced technologies like Computer-Aided Design (CAD), the department ensures precision in creating new molds and swiftly modifies existing ones in response to design changes or production issues. Rapid mold modification and repair capabilities contribute to minimizing downtime, enhancing overall production efficiency, and maintaining high standards of product quality. This comprehensive in-house capability allows companies, such as Texlon Plastics, to have control over the entire mold lifecycle, facilitating adaptability to changing production needs and ensuring the seamless operation of their injection molding services.